What is compounding?

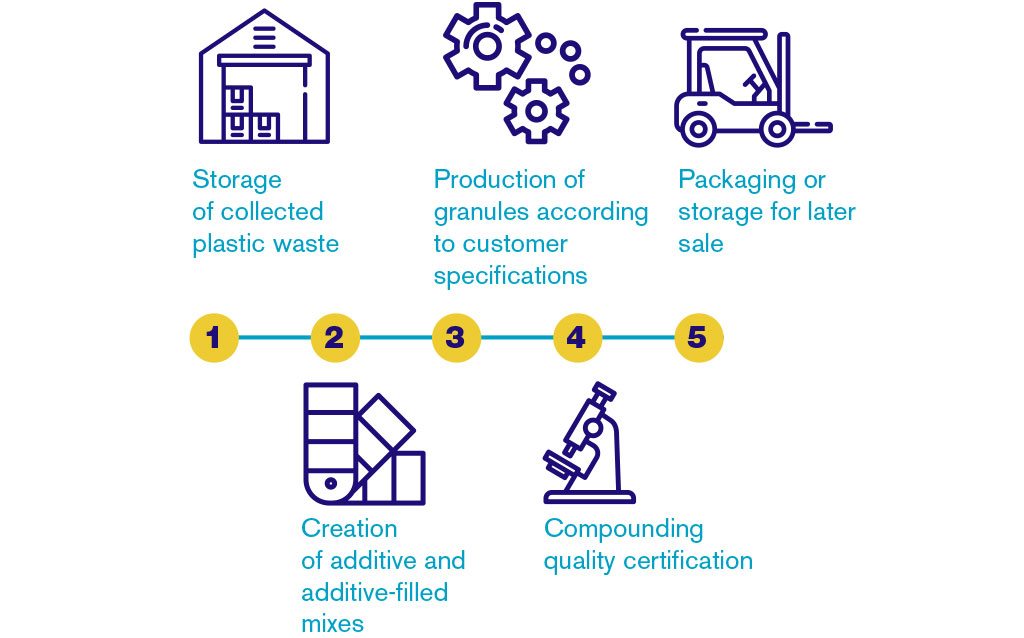

Compounding is a mixing process whereby molten polymer resin is combined with reinforcements, other polymers, pigments, modifiers and additives that improve properties and processability.

With compounding, we can obtain formulated, additive and additive-filled polymers.

Compounding production cycle

Our products

We advise you on mixing and producing new plastic materials and on developing and optimising the customised formulation that you desire.

We develop the most suitable additives, fillers and reinforcements to meet the product’s technical requirements and specifications.

We offer you solutions for dispersion in fillers, fibres and pigments to achieve the greatest chemical and mechanical properties.

The products obtained from the compounding process are classified as formulated, additive and/or filled polymers.

Applications

Our production processes subject different products, such as virgin, sub-standard and shredded granules, to different additive and control processes to create a raw material intended for multiple applications in very different sectors.